Dear Customer,

Thank you for choosing the Prins CNG Dual-Fuel system for your truck. This system has been designed to meet stringent international safety standards.

Before Driving:

We recommend that you carefully read this manual before operating your vehicle on Dual-Fuel. This document provides essential information about your Prins system, including its features and proper operation.

KEY INFORMATION

This manual will guide you through the safe and efficient use of your CNG system. It includes valuable information such as:

- General information for driving on CNG Dual-Fuel

- Compressed Natural Gas (CNG) and fuel quality

- System components and functions

- Operating the Prins CNG Dual-Fuel HD system

- Fueling procedures

- Maintenance and trouble shooting

GENERAL INFORMATION FOR DRIVING A CNG DUAL-FUEL VEHICLE

1. Diesel Fuel Management:

Primary Fuel: Diesel remains the engine's primary fuel source.

Compressed Natural Gas (CNG) is used in addition to diesel under specific engine load and speed conditions.

Avoid Running Out: Always ensure there is sufficient diesel fuel in the tank, as diesel is consumed continuously during operations.

2. Prioritize Maintenance:

Adhere to the vehicle's regular maintenance schedule and the detailed maintenance schedule for the Prins system provided.

NOTE: The truck/engine maintenance intervals may be different from similar trucks/engines that operate on diesel only. See chapter "Maintenance" for more detailed information.

3. Gas Leak Detection and Response:

Immediate Action: If you smell gas, immediately switch off the CNG system.

Manual tank valves: Close the manually operated valves on the CNG tanks.

Seek Service: Have your truck inspected by a qualified service technician as soon as possible.

4. Abnormal Combustion:

If you hear any unusual sounds from the engine, immediately switch back to diesel-only operation by pressing the fuel selection switch.

NOTE: In some applications the fuel selection switch may be disabled. In this case, come to a safe stop and shutdown the engine. Close manual valve and/or manual tank valves, and re-start the engine.

If the engine runs and sounds fine in diesel-only mode, continue your trip in diesel-only mode, and visit a Prins authorized workshop as soon as possible. If the unusual sound is still present, even in diesel-only mode, shutdown the engine, and call roadside assistance according to your company policy.

COMPRESSED NATURAL GAS (CNG)

Compressed Natural Gas (CNG) is a fuel derived from natural gas (which can be renewable). Natural gas is formed over millions of years through the decomposition of organic matter. For use in vehicles, it is compressed to 200-250 times its atmospheric pressure and stored in specialized tanks. CNG is a clean fuel, produces less CO2.

FUEL QUALITY

The natural gas used must meet, at a minimum, the standards specified in SAE J1616 or ISO 15403:2005, and must contain a methane number of at least 85. Use of fuel that does not meet these specifications will void all warranty terms.

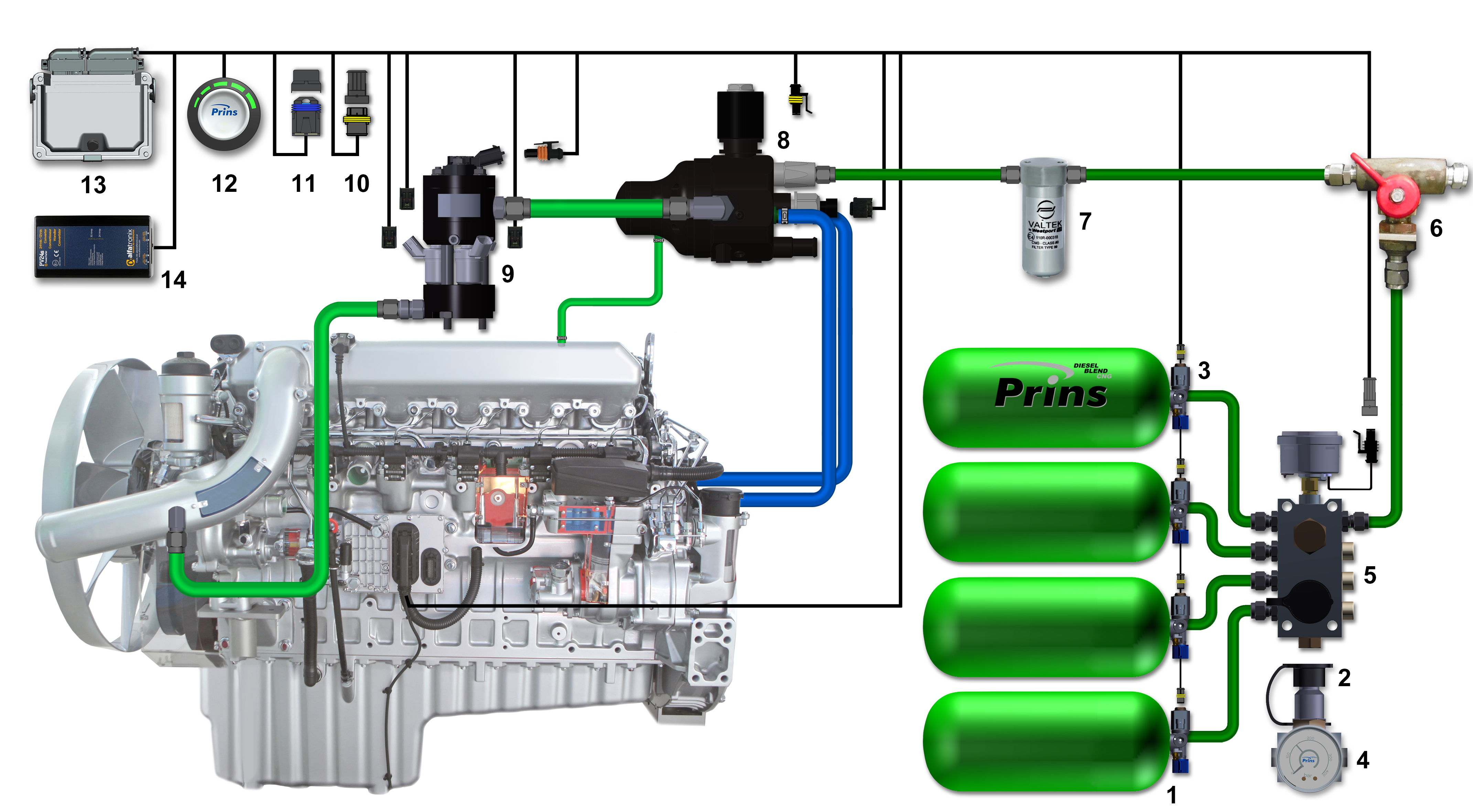

THE PRINS CNG DUAL-FUEL HD SYSTEM

The Dual-Fuel system introduces CNG into the engine intake manifold.

Your CNG Dual-Fuel HD system may have slight variations from this diagram.

PRINS CNG DUAL-FUEL HD COMPONENTS

The CNG tanks are mounted on the truck. The Compressed Natural Gas (CNG) is stored in these tanks under high pressure.

The CNG filling receptacle is (usually) mounted near the CNG-tanks on a tank coupling block (5). In most countries NGV-1 or NGV-2 connections are used. Depending on your configuration, either one or both filling valves may be fitted. Optionally there may be receptacles on both sides of the vehicle. The filling receptacle is equipped with a dust cap, to prevent dirt and/or moisture ingress.

Each CNG tank is equipped with a cylinder valve, which can be operated manually or automatically. A cylinder valve has safety features, such as a thermal safety valve (activated by fire), an excess flow valve (activated by overpressure), or a burst disc (also for overpressure).

Manual cylinder valve:

The CNG tank can be closed using the manual valve. In the closed position, neither CNG withdrawal nor CNG filling is possible.

Automatic cylinder valve:

During the switch-over procedure and dual-fuel operation, the solenoid valves are powered by the AFC. When the engine operates in diesel-only mode, the solenoid valves remain closed. When the solenoid valves are not powered, they function as a check valve, allowing flow in only one direction. This design enables the tanks to be filled even when the solenoid valves are not powered. An automatic cylinder valve also includes a built-in manual valve. When this manual valve is in the closed position, it is not possible to fill the tank.

Installed in the tank coupling block, the manometer or pressure sensor measures the pressure in the high-pressure line leading to the engine. It indicates the CNG amount.

A tank coupling block can be installed near the CNG tanks. This component consolidates the fuel lines from the CNG tanks, allowing a single fuel line connection to the engine components. Filler receptacles (NGV-1, NGV-2), a manometer or pressure sensor may be mounted on this block.

An optional manual shut-off valve may be present in the gas supply line between the tanks and the high-pressure filter. This valve allows for the isolation of the engine system from the CNG tanks for maintenance or servicing. It is typically located behind the cab.

The high-pressure coalescent filter is installed upstream of the pressure regulator. Its function is to filter out solid contaminants and separate oil and moisture from the gas. Collected liquids can be drained from the filter after the system has been depressurized.

The pressure regulator reduces the high tank pressure to the system operating pressure. This regulator incorporates a built-in solenoid valve and a pressure sensor.

The Filter Injector Unit (FIU) is installed downstream of the regulator. This unit integrates a low-pressure filter, which cleans the low-pressure gas before it reaches the injectors, and the injector housing. The injectors then accurately meter the amount of gas to the engine. Additionally, the FIU incorporates a pressure-temperature sensor that measures the gas pressure and temperature.

The diagnostic connector is usually located within the fuse/relay box in the dashboard. This connector allows for the diagnosis and monitoring of the Dual-Fuel system using dedicated diagnostic software and a PDT interface.

The fuses protect the electronic circuit from overloading and are usually located in the trucks fuse/relay box in the truck dashboard.

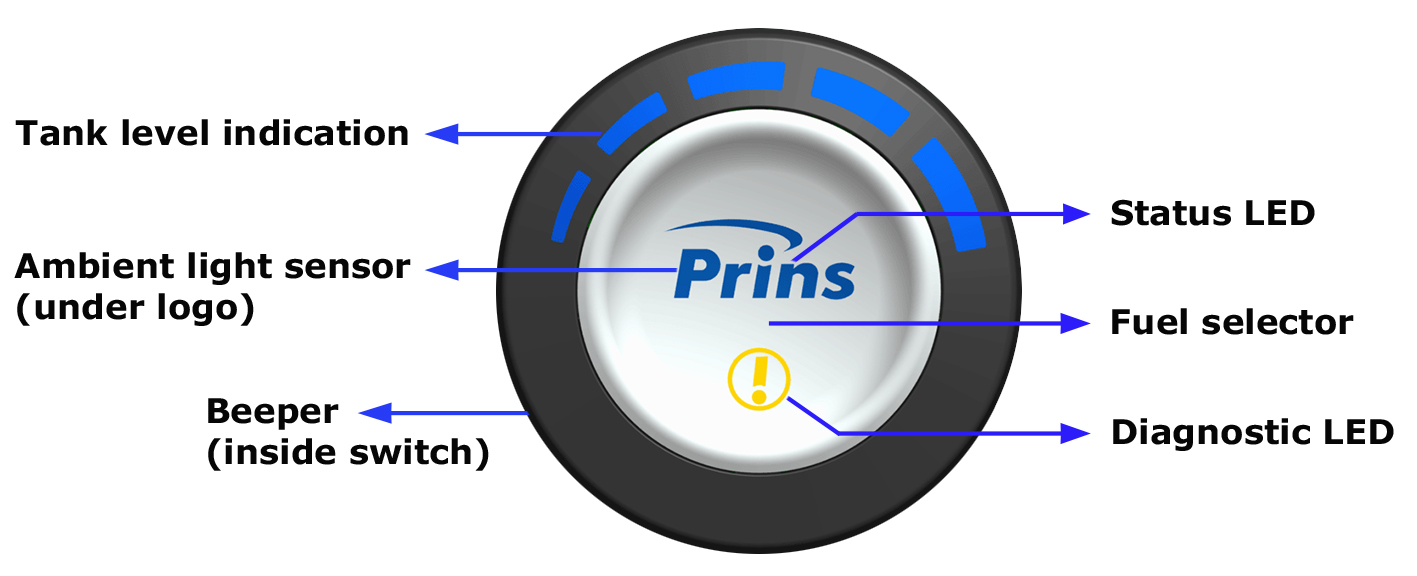

The fuel selection switch is located on the dashboard. This switch enables the driver to select the desired fuel, provides an indication of the fuel tank content, and can display system error codes.

The AFC is located inside the truck cabin. This computer receives and processes all incoming signals and controls the various actuators in the Dual-Fuel system.

The DC/DC converter is usually in the truck’s fuse/relay box in the truck dashboard. This converter is needed for using 12-volt components in a 24-volt vehicle.

OPERATING THE PRINS CNG DUAL-FUEL HD SYSTEM

Starting

The engine will always start on diesel only, even when dual-fuel operation is selected.

Only after the engine has reached the appropriate operating conditions, the system switch to dual-fuel mode.

During this switch-over period, the Prins logo in the switch will be flashing, indicating that dual-fuel is selected, but not yet active. Once the system has switched to dual-fuel operation, the Prins logo will remain lit permanently.

Switching from diesel to Dual-Fuel and reverse

While driving, you can manually switch between diesel and dual-fuel operation at any time by pressing the fuel selector switch.

NOTE: In some applications the fuel selection switch may be disabled.

Pressing the switch will still acknowledge Tank Empty or Fault Detection, but switching to diesel-only operation by pressing the switch is not possible.

The fuel selector switch

The status LED (Prins logo) has four operating modes:

1. Engine off: LED is on.

2. 100% diesel mode: LED is off.

3. Dual-Fuel mode selected, but running diesel-only: LED is flashing.

4. Dual-Fuel mode: LED is on.

The switch has a built-in light sensor. The brightness of the LEDs adjusts automatically based on the ambient light.

Fuel level indication

The fuel level is indicated by five LEDs, each LED representing approximately 20%. When the tank level drops below 10%, the last of the LED’s changes color to red.

You can still drive in dual-fuel mode to consume the remaining CNG. Once the tank pressure drops too low to maintain sufficient pressure for the injectors “Tank Empty detection” will be triggered.

Empty tank situation

When the CNG pressure in the low pressure filter becomes too low for proper operation of the CNG injectors, this is usually the result of a too low CNG tank pressure.

If this situation occurs, the system will automatically switch back to diesel-only operation. The fuel status LED will start to flash, and the beeper will sound three times. No further driver action is required.

After each start of the engine the system will go through the normal switch-over procedure. If the pressure is still too low, the system will again detect the empty tank situation. Once the CNG tanks have been refilled, the system will automatically switch to Dual-Fuel mode after starting the engine and completing the switch-over procedure.

Diagnosis

A diagnostic LED and a beeper are integrated into the switch to indicate any system faults to the driver.

The following fault conditions may occur:

Non-critical fault: The diagnostic LED flashes.

Diagnosis:

A fault has occurred in the Dual-Fuel system. It is still safe to drive in Dual-Fuel mode, and the environmental impact remains within acceptable limits.

Action:

Have the system checked at a Prins authorized service location.

Critical fault: The system automatically switches back to diesel-only operation. The beeper will sound,

and the diagnostic LED will remain constantly illuminated. The Status LED will be flashing.

Diagnosis:

A critical fault has occurred in the Dual-Fuel system. Driving in Dual-Fuel mode is no longer possible. Therefore, the system has automatically switched to diesel-only operation.

Action:

Silence the beeper by pressing the switch. Have the system checked at a Prins authorized service location.

Always follow filling station procedures and instructions!

The CNG tanks must be filled as follows:

• Turn off the engine!

• Remove the dust cap from the receptacle, and make sure the receptacle is clean and dry.

• Attach the fill nozzle to the receptacle.

• Start the fill process on the dispenser.

• The dispenser will stop automatically when the maximum tank pressure is reached.

• Now remove the fill nozzle from the filling receptacle.

• Make sure the dust cap is clean and dry before putting it back onto the receptacle.

WARNING:

Smoking and open flames are strictly prohibited while refueling the CNG tanks.

At most filling stations the use of mobile phones is not allowed.

Disassembly of parts/system

Due to the high pressure inside the system, never disconnect or disassemble any components of the Dual-Fuel system. Only Prins authorized workshops should perform any removal or repair work on the system.

Gas leakage

If you suspect a gas leak, immediately switch off the Dual-Fuel system and close the manual valves. Then, contact an authorized Prins dealer as soon as possible.

Fire

In the event of a fire, evacuate the truck immediately and move to a safe distance. Always inform the emergency services that the truck is equipped with a CNG Dual-Fuel system.

General truck maintenance should be performed by a truck importer's authorized workshop.

Sulphur based odorants may be added to the CNG to aid in leak detection.

These or their combustion products may enter the crankcase and result in accelerated deterioration of the engine oil. A shorter oil change interval or better oil quality may be required.

We therefore recommend periodic engine oil sampling and analysis to establish a safe OCI.

Maintenance and repairs specific to your Prins Dual-Fuel system must only be carried out by an authorized Prins (or Prins importer) dealer.

Maintenance overview table for the Prins Dual-Fuel system, see download at the bottom of this page.

Deviations from this table are allowed, for example to align the Dual-Fuel system maintenance intervals with the general truck maintenance, as long as the intervals in the table are not exceeded.

If your truck does not run on Dual-Fuel, please check the following:

• Is there sufficient gas in the tank?

• Check the Dual-Fuel system fuses for any defects.

• Check if the manual cylinder valves and the (optional) manual shut-off valve are open.

• Do not attempt further repairs or adjustments, but have the system checked by a Prins authorized workshop.

IMPORTANT: Never use a fuse with a higher rating than specified. Doing so may cause damage to the system and/or the vehicle.

If you are unable to resolve the issue, please contact your local Prins dealer or the official Prins importer for your country. Do not attempt any repairs or adjustments yourself. All repairs and adjustments should be performed by an authorized Prins Dealer. Failure to do so will void the warranty on your Prins Dual-Fuel system.

In case you are stranded by the roadside, and need to completely disconnect the dual-fuel system, follow the procedure below:

• Close all manual valves.

• Remove the fuses from the Prins Dual-Fuel system.

• Remove the CAN-bus break-out connection from the vehicle and reconnect the original wiring harness.

This connection is typically made in the truck dashboard, near the truck’s fuse box.

• Remove all the dual-fuel system break-out connections from engine sensors, such as boost pressure

and fuel rail pressure sensor, and reconnect the original wiring harness.

Note: This procedure should only be performed by a qualified roadside assistance service.

When performing damage repairs on a vehicle equipped with gas tanks (e.g., CNG) and the truck is placed in a spray/dry booth with a drying temperature exceeding 60°C, ensure that the system pressure does not exceed 50 bar.